1. 牌號 Grade 5CrNiMoV/55NiCrMoV7/1.2714/6F3

1. 牌號 Grade 5CrNiMoV/55NiCrMoV7/1.2714/6F3

|

GB |

DIN |

W-Nr. |

AISI |

JIS |

BS |

EN |

|

5CrNiMoV |

55NiCrMoV7 |

1.2714 |

6F3 |

|

|

|

2. 執行標準 Standard GB/T1299-2014 DIN EN ISO4957 ASTM A681

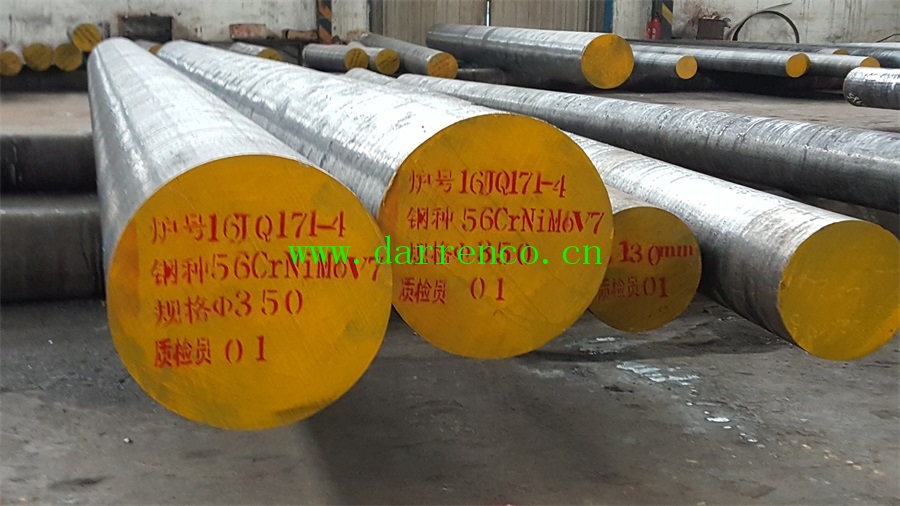

3. 尺寸、外形、允許偏差 Size , shape ,tolerance

|

狀態 condition |

公差 tolerance |

|

磨皮 grinding surface |

-0/+5mm |

|

車削 machined surface |

-0/+3mm |

|

自由長度 free length |

4-6m |

|

定尺長度 fixed length |

-0/+50mm |

|

超長 over long |

7-23m |

|

彎曲度 straightness |

≦3mm/m, 總彎曲度total straightness length ≦ total length總長度0.5% |

|

不圓度 ovality |

不大于公稱直徑公差的0.7倍 Not greater than 0.7 times the nominal diameter tolerance |

|

鍛材生產直徑范圍forged bar dia range |

140-600mm |

4. 冶煉方法 smelting process

電弧爐+爐外精煉+真空脫氣冶煉,下注鋼錠,電渣重熔需在合同中注明 EAF+LF+VD bottom pour ingot, ESR need indicate in contract

5. 交貨狀態 delivery condition

退火磨氧化皮、車光、正火、調質,交貨狀態需合同注明 annealed grinding surface. If need machining, normalizing or Q&T need indicate in contract

6. 化學成份 chemical composition

|

Grade |

C |

Si |

Mn |

P |

NI |

Cr |

V |

Mo |

|

DIN 1.2714 |

0.50 |

0.60 |

0.10 |

0.40 |

0.65 |

0.95 |

0.03 |

1.50 |

1.80 |

1.00 |

1.20 |

0.07 |

0.12 |

0.45 |

0.55 |

|

ASTM 6F3 |

0.50 |

0.60 |

0.10 |

0.40 |

0.65 |

0.95 |

0.03 |

1.50 |

1.80 |

1.00 |

1.20 |

0.07 |

0.12 |

0.45 |

0.55 |

其他元素檢測需要合同注明 other elements test result need indicate in contract.

7. 交貨硬度 hardness

|

牌號grade |

退火狀態交貨硬度 annealing condition hardness HBW ≦ |

試樣淬火硬度test specimen hardness after Q&T |

|

淬火溫度Q&T ℃ |

冷卻劑cooling agent |

洛氏硬度HRC ≧ |

|

1.2714 |

229 |

830-900 |

空氣 air |

64 |

8. 低倍組織 酸浸低倍試片上不得有目視可見的縮孔、夾雜、分層、裂紋、氣泡和白點。Macrostructure No visible shrinkage, inclusion, delamination, cracks,

bubbles or white spots should be observed on the acid – soaked sample piece

|

鋼材直徑diameter mm |

1組 group |

2組 group |

|

中心疏松 center porosity |

錠型偏析segregation |

中心疏松center porosity |

錠型偏析segregation |

|

級,不大于 class ≦ |

|

≦80 |

2.0 |

2.0 |

3.0 |

3.0 |

|

>80-150 |

2.5 |

3.0 |

3.5 |

3.0 |

|

>150-250 |

3.0 |

3.0 |

4.0 |

4.0 |

|

>250-400 |

3.5 |

3.0 |

4.5 |

4.0 |

|

>400 |

協商 Negotiate |

電渣鋼合格級別供需雙方協議 ESR steel qualified level need negotiate.

9. 顯微組織 microstructure

1) 珠光體組織 合格級別1-5級,熱壓力加工用鋼不檢測 pearlite 1-5 class

2) 網狀碳化物 直徑不大于60MM合格級別不大于3級 carbide network ≦ 3 class

3) 共晶碳化物不均勻度(冷作模具鋼檢測)Eutectic carbide inhomogeneity

|

鋼材直徑diameter MM |

共晶碳化物不均勻度合格級別Eutectic carbide inhomogeneity qualified level |

|

1組group |

2組 group |

|

級,不大于 class ≦ |

|

>120-400 |

6 |

協議Negotiate |

|

>400 |

協議Negotiate |

協議Negotiate |

10. 非金屬夾雜物 nonmetallic inclusion

電渣鋼結果符合1組,真空脫氣鋼符合2組 ESR steel conform to 1 group , VD steel conform to 2 group

|

非金屬夾雜物類別nonmetallic inclusion type |

1組 group |

2組 group |

|

細系thin series |

粗系heavy series |

細系thin series |

粗系heavy series |

|

級,不大于 class ≦ |

|

A |

1.5 |

1.5 |

2.5 |

2.0 |

|

B |

1.5 |

1.5 |

2.5 |

2.0 |

|

C |

1.0 |

1.0 |

1.5 |

1.5 |

|

D |

2.0 |

1.5 |

2.5 |

2.0 |

11. 脫碳層 decarburized layer

脫碳層深度不大于0.25+1%D,直徑大于150mm雙方協議 decarburized layer depth not greater than 0.25+1%D, diameter over 150mm negotiate.

12. 超聲檢測 UT test

執行標準GB/T6402-2008,常規規格執行D/d級,直徑400以上雙方協議,鋼材內部不允許有白點、夾渣、分層、內裂、縮孔等冶金缺陷 standard as per

GB/T6402-2008 /SEP1921 C/c or D/d class. No white spot, slag inclusion, delamination, cracking, shrinkage and other metallurgical defects are

allowed inside the steel

|

缺陷尺寸級別 defect size level |

單個缺陷平底孔直徑single FBH mm |

連續缺陷平底孔直徑continuous FBH mm |

連續缺陷最大長度continuous FBH length mm |

|

C |

7 |

5 |

40 |

|

D |

5 |

3 |

30 |

|

E |

3 |

2 |

30 |

|

缺陷數量級別defect qty level |

單個缺陷數量single FBH QTY |

連續缺陷數量continuous FBH QTY |

|

個數,不大于 number ≯ |

|

c |

8 |

4 |

|

d |

4 |

2 |

|

e |

2 |

1 |

13. 表面質量 surface quality

鍛材表面沒有目視可見的裂紋、折疊、結疤和夾雜,如有上述缺陷就清除,深度不大于截面尺寸4%,清除寬度不小于深度的5倍,There are no visible

cracks, folds, scars or inclusions on the surface. If there are any of the above defects, they should be removed with a depth not greater than

4% of the section size and a width not less than 5 times of the depth.

14. 特殊要求 special requirements

超出標準約定范圍的供需雙方協議 The buyer and the seller negotiate beyond the agreed scope of the standard

15. 起訂量 交貨期 MOQ 25 tons , 30 days delivery time.

16.特點及用途 features and applications: 是非常推薦用于緊密模鍛件,因為它具有高耐磨、高韌性、高硬度的特性,可以用鉻鎳鉬釩高梯度合金來

實現。熱工模分為錘鍛、模鍛、擠壓和壓鑄幾種主要類型,包括熱鍛模、壓力機鍛模、沖壓模、熱擠壓模、金屬壓鑄模。熱變形模具不僅承受著巨大的

機械應力,而且在反復工作過程中還會產生熱應力。熱工模鍛鋼不僅要具有較高的硬度、紅硬度、耐磨性、韌性,還要具有優良的高溫強度、熱疲勞穩

定性、導熱性、上部硬化能力,以保證整個截面力學性能一致。DIN 1.2714 is highly recommendable for Close Die Forgings due to its characteristics

of high wear-resistance, extra toughness , high hardness which is achieved with Cr-Ni-Mo-V high graded alloys. Hot-work die divides into several main

types, such as hammer forging, die forging, extrusion and die casting, including hot forging die, press machine forging die, stamping die, hot-extrusion

die, metal die-casting mould. Heat distortion mould not only supports huge mechanical stress, but also thermal stress during working repeatedly.

Hot-work die steel should have not only high hardness, red hardness, abrasion resistance, toughness, but also have excellent high temperature strength,

thermal fatigue stability, thermal conductivity, upper harden-ability for guaranteeing the whole cross section with consistent mechanical property.

優勢 advantage

工藝成熟,煉鋼采用氣體保護澆注,快鍛機開坯,徑鍛機成材并球化退火,鍛造頻率高恒溫鍛造有利于消除沿晶界分布的網狀碳化物。pouring by gas

protected , blooming by fast forging machine, forming by radial forging machine and spheroidize annealing, forging with high frequency and constant

temperature is helpful to eliminate the reticulated carbides distributed along the grain boundary.